Aesthetics of paint, but up to 15x stronger—thin-film polyurea is durable, flexible and UV-stable

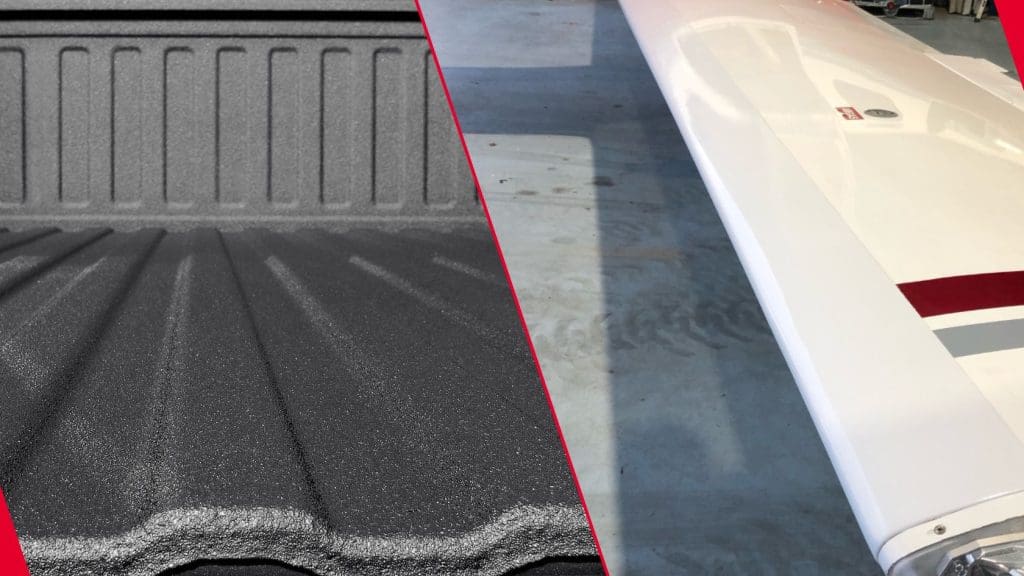

Think polyurea, and the first image to come to mind may be a truck bedliner with its thick, beefy coating and coarse, industrial appearance. That image, however, would be a misnomer. Many of today’s advanced polyurea coatings—pioneered by Ultimate Linings over the past decade—are ultra-thin but yield ultra-strong levels of protection for a wide range of applications, from automotive to construction. Thin is in.

Applied strength of polyaspartic chemistry

Make no doubt, thick-film polyurea coatings certainly have their place, protecting earth-moving equipment, industrial machinery, military vehicles, and yes, bedliners, from impacts, abrasion and corrosion.

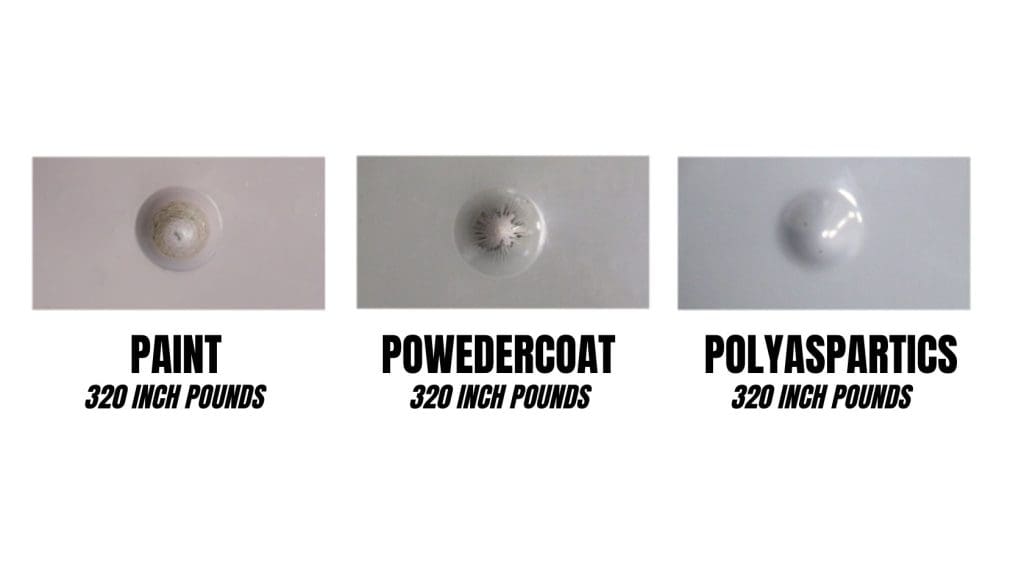

But Ultimate Linings’ thin-film products—commonly categorized as a polyaspartic and recognized as an advancement in polyurea chemistry—deliver comparable protection to their thicker brethren while offering improved aesthetics and exceptional color stability. This makes thin-film polyurea a practical substitute for traditional paint and powder coating applications, offering a visually pleasing appearance but with superior strength and durability, greater flexibility, and outstanding chemical resistance. In fact, thin-film polyurea has proven to be up to 15x stronger than powder coating and paint treatments.

“The sleek, durable alternative to thick coatings—stronger than paint, more flexible than powder coatings.”

And that means wherever paint or powder coatings are used—pipe coatings, railings and signs, toolboxes, lawn tractor cowls and shields, automotive parts and accessories, playground equipment, and more—a thin-film polyurea from Ultimate Linings should be considered for its numerous advantages and performance characteristics, including:

- Durability—high abrasion and chemical resistance protects surfaces from harsh conditions, impacts, and spills

- UV stability—won’t yellow or degrade under UV exposure, making them ideal for outdoor and sun-exposed environments

- Hot and cold versatility—can be applied in a wide range of temperatures without affecting performance

- Fast curing time—can be applied on-site with curing at room temperatures (no oven needed), all of which speeds return to service of equipment and machinery and accelerates production cycles with less energy use

- Zero VOC emissions—emits zero volatile organic compounds (contains no solvents) compared to traditional coatings, complying with environmental and health standards

Application versatility

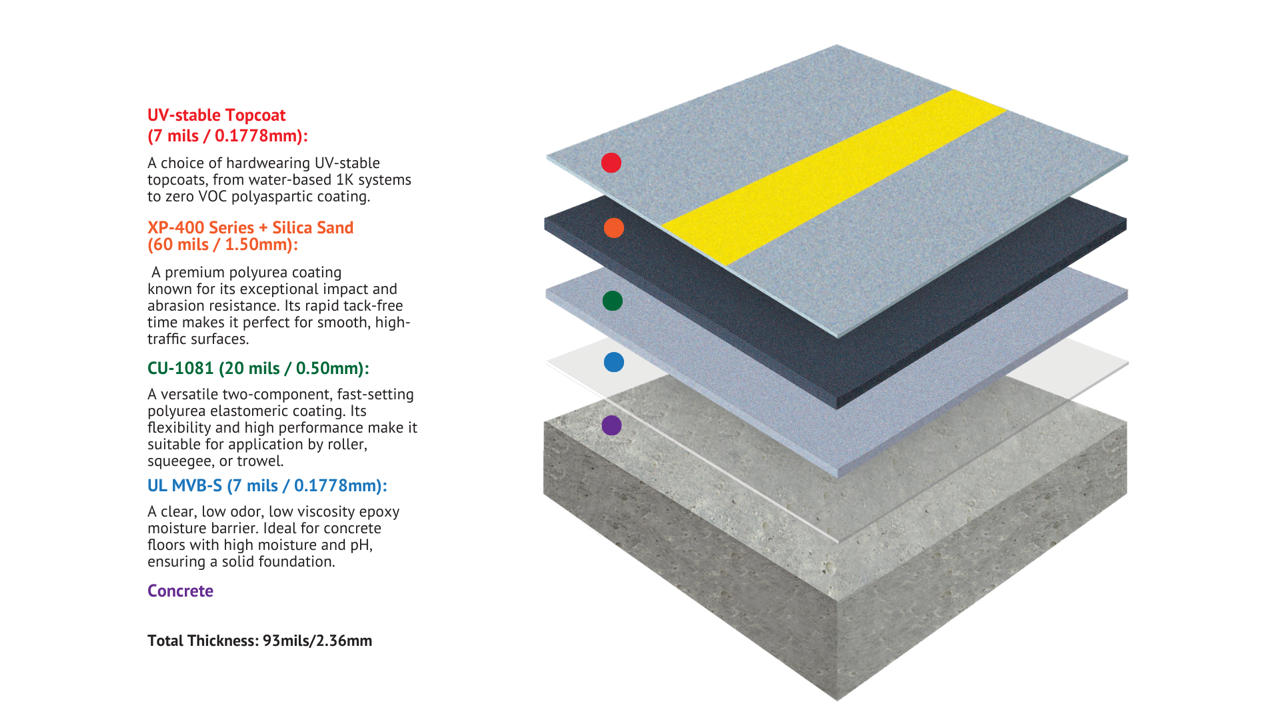

Polyaspartic polyureas are as diverse and functional as their many applications. These thin-film polyureas are the most-specified, UV-stable topcoat for aromatic, thick-film polyurea coatings, providing color stability, better aesthetics, and added protection in a range of applications.

The construction sector is a case in point. Applied as a final topcoat for UV color stability, polyaspartic polyurea is a sought-after coating treatment in the industry, stopping water intrusion on roof tops, underground garages, patios and walkways, and more. Ultimate Linings has developed specific systems and custom chemistries for waterproofing construction structures.

And construction is just the beginning. Originally introduced as a protective coating for garage and warehouse floors due to their resistance to heavy foot and vehicle traffic, polyaspartics are also now being used by metal fabricators, boat builders, theme parks, and other diverse industries.

Whether for industrial, commercial or residential applications, Ultimate Linings’ thin-film polyurea technology is a smart solution that offers significant advantages over paints and powder coatings. It also delivers similar protection to thicker-film coatings.

Thick? Thin? It all depends on the application and your process needs. Ultimate Linings can develop the ideal coating solution for you, providing Ultimate protection for years.