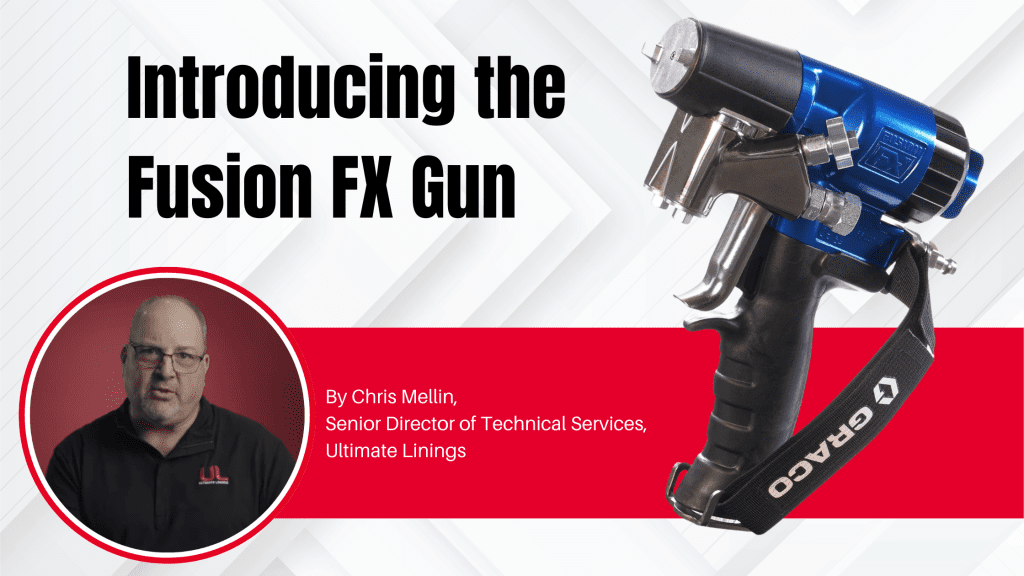

Author: Chris Mellin, Senior Director of Technical Services, Ultimate Linings

Introduction: The Game-Changing FX Gun

As the polyurea spraying industry continues to evolve, the tools we use must advance alongside it. Enter the Graco Fusion FX Gun—a cutting-edge solution designed with the applicator’s needs in mind. The FX Gun represents the next generation of spraying technology, offering a lighter, well-balanced tool that’s easier to maintain, helping to reduce fatigue and minimize downtime. The result? Enhanced productivity and an improved user experience.

Although Graco has not finalized the launch date of their high-pressure version, (as they refine the mix chamber seal material), the introduction of the Fusion FX Gun marks a significant milestone. It’s set to reshape the spraying industry by addressing key challenges faced by applicators and raising the bar on what’s possible with spray guns.

How the FX Gun Compares to Existing Fusion Guns

Graco’s Fusion series has long been a cornerstone in the industry. Since the launch of the Fusion AP in 2003, these spray guns have been celebrated for their user-friendly design and reliable performance. The 2020 release of the Fusion PC introduced a replaceable cartridge system, simplifying maintenance and extending the gun’s life expectancy—qualities that quickly made it a favorite among applicators.

The Fusion FX Gun takes these advancements even further, setting a new standard for comfort, efficiency, and safety.

Key Improvements in the Fusion FX Gun

- Ergonomic Design: The FX Gun is 30% lighter than its predecessors and features a better-balanced design, making it easier to maneuver. The smaller front end allows for access to tight spaces, while the composite handle minimizes heat transfer, reducing fatigue during extended use.

- Enhanced Trigger Action: A shorter trigger throw makes the FX Gun more responsive, enabling smoother operation.

- Simplified Maintenance: The FX Gun revolutionizes mix chamber servicing. Unlike traditional guns, where the chamber is a frequent source of failure and requires the gun to be taken offline, the FX allows for quick chamber removal by simply detaching the air cap. This saves valuable time and reduces downtime significantly.

- Side Seal Elimination: One of the most common failure points in previous models was the side seal surfaces. The FX Gun eliminates this issue entirely with its DuoFlo valving, which keeps the mix chamber stationary. This innovation increases the life expectancy of the cartridge and reduces maintenance headaches.

- Improved Cartridge Replacement: Graco has streamlined the cartridge replacement process. Applicators can remove the fluid manifold, twist the cartridge, and replace it with minimal effort. Larger filters, tool-free shut-off valves, and on-gun servicing further enhance usability.

- Safety Features: Check valves prevent material flow when the gun is removed while under pressure, addressing a critical safety concern.

Performance and Application Enhancements

One of the most exciting advancements is the improved spray pattern. Traditional air-purge guns often concentrate material in the center of the spray pattern, requiring a 50% overlap for consistent coating. The FX Gun, with its newly designed chambers, delivers a fuller, more even pattern across the entire diameter. This reduces the need for overlap, significantly decreasing application time while ensuring uniform coverage.

Ultimate Linings and Graco: A Strategic Partnership

At Ultimate Linings, innovation is at the core of our commitment to advancing technology in the polyurea spraying industry. Through the subsidiaries of our parent company, IXS Coatings, I have had the privilege of collaborating directly with Graco on numerous groundbreaking projects. These include the development of the Fusion PC Gun and the Reactor 3 electric reactors, each designed to address the real-world challenges faced by applicators. Our hands-on input has been instrumental in refining Graco’s designs, ensuring that each innovation delivers exceptional performance and usability for the spraying community.

The Fusion FX Gun is another milestone in this ongoing partnership. During the development phase, Graco worked closely with our team, conducting tests in our spray lab to perfect the mix chamber design. This collaboration has extended to exciting new developments, including the Fusion FX Auto for automation and testing the Reactor 3 hydraulic version.

Conclusion: A Game Changer for the Spraying Industry

After more than two years of trials and testing, the high-pressure version of the Fusion FX Gun has proven itself as a game changer. Its ergonomic design, simplified maintenance, and superior performance will make it the best tool currently available for polyurea applicators. By addressing long-standing issues with existing spray guns and introducing a host of innovative features, the FX Gun is poised to revolutionize the industry.

For those of us in the field, the high-pressure Fusion FX Gun represents not just an evolution, but a revolution in polyurea spraying technology. I look forward to seeing it in action across job sites and witnessing the difference it will make for applicators everywhere.

Stay tuned for updates on the official release of the High-Pressure Fusion FX Gun. In the meantime, we’re here to help you explore how this breakthrough technology can transform your polyurea and foam spraying projects.

Author Bio:

My name is Chris Mellin, Senior Director of Technical Services at Ultimate Linings. With over 25 years of experience in the polyurea and foam industry—and credentials that include SSPC C1/C2, Fanuc, and Graco Master Technician certifications—I’ve seen firsthand how the right tools can transform an applicator’s work. The Fusion FX Gun is precisely that kind of transformational innovation.