THE ULTIMATE for Defense Personnel and Assets

Home » Industries Served » Defense Industry

Advanced Protection Tailored for Military and Defense Applications

In defense and security applications for government or private industry, Ultimate Linings develops advanced protective coatings under our PAXCON brand that shield personnel, armored vehicles, support equipment, and infrastructure. Our cutting-edgepolyurea solutions are at work around the world, enhancing safety and durability in life-threatening conditions, all while offering a strong, first line of defense against corrosion because of moisture, temperature variations, and salt spray. Rely on Ultimate protection with the performance of PAXCON polyurea coatings from Ultimate Linings.

Ultimate Linings Key Benefits

Formulated for the military and security industry, PAXCON coatings deliver:

– High impact performance that absorbs and dissipatesenergy from blasts and projectiles and protects against resulting injury and damage from fragmentation

– Resistance to corrosion and abrasion, resulting in superior durability and extended service life of military assets

– Flexible and seamless application and excellent bonding characteristics on various surfaces and structural materials, including wood, steel, concrete, and cinder block

– Customizable solutions that ensure optimum performance across a wide range of equipment and harsh environments

– Fast, spray-on application and rapid cure times, which synch with time-sensitive military operations and maintenance schedules and reduce costly downtime

– Light in weight protection that won’t hinder performance of personnel or equipment

Application Types in the Defense Industry

Our spray-on polyurea coatings are provenreliable for a wide range of military and security applications:

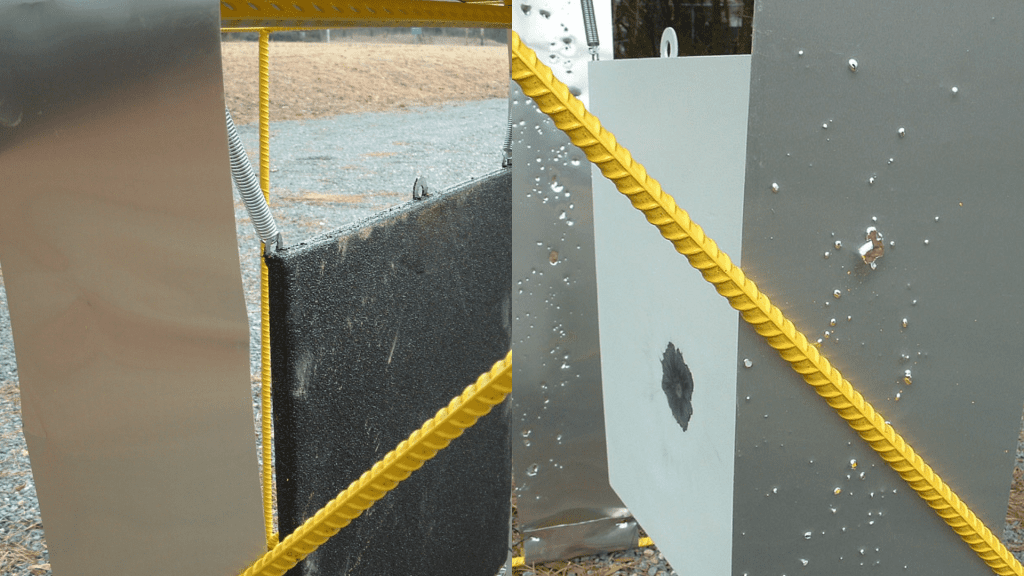

Body Armor and Spall Linings:Applied to materials like Dyneema® and ceramic panels, our defense-grade hybrid formulation(PX-2100) significantly enhances the effectiveness of body armor and vehicle spall linings, preventing dangerous fragmentation and spalling that can cause severe injuries.

Blast Mitigation for Structures: Walls and buildings coated with our blast-mitigation pure polyurea (PX-3350) can endure impacts from explosions significantly greater than those with standard coatings. OurEnergy Resistant Coating (ERC) technology allows structures to flex and absorb explosive energies, mitigating the risk of fragmentation and providing crucial additional escape time for personnel.

Corrosion Control for Military Vehicles: A protective polyurea layer shields against harsh environmental and chemical elements, maintaining structural integrity under challenging conditions and extending operational life and reliability.

Defense Asset Protection: From helmets and torsion bars to trailers, PAXCON coatings provide a durable, protective layer that withstands mechanical wear and environmental hazards, ensuring that defense assets remain operational. Our coatings also provide a slip-proof grip for extra personnel safety.

Gallery

Click/tap to enlarge image:

Why Ultimate Linings?

Manufacturing Capabilities

Quality Control

24/7 Technical Support

R&D Lab

Over 35 years of experience

300,000+ sq ft purpose-built facility

State-of-the-art equipment

Full on-site innovation and quality labs

On-site application booths

International shipping capability

Partner With Ultimate Linings

Protect your military and security assets with the best in polyurea coatings. Partner with Ultimate Linings today and experience the difference.

Frequently Asked Questions

Are any products from Ultimate Linings/PAXCON bulletproof?

No, this is a common misconception. PAXCON, when used as a spall liner, is applied over armored panels. The armored panels are responsible for stopping the bullet, while the spall liner (PAXCON PX-2100) captures and contains the bullet’s fragments. Without the spall liner, these fragments would scatter and pose a significant risk of injury. The primary function of the spall liner is to prevent these sharp fragments from causing harm to military personnel.

How does Ultimate Linings protect military vehicles and assets from corrosion?

Polyurea coatings by Ultimate Linings provide a robust barrier against environmental factors that cause corrosion. These coatings adhere strongly to metal surfaces, creating an impermeable layer that resists moisture, chemicals, and other corrosive agents. By preventing rust and degradation, polyurea coatings extend the lifespan of military vehicles and assets, ensuring they remain operational and reliable in harsh conditions.

What role does impact protection play in the maintenance of military defense assets, and how does polyurea help?

Impact protection is crucial for maintaining the structural integrity and operational readiness of military defense assets. Polyurea coatings absorb and distribute the force from impacts, minimizing damage and reducing the need for frequent repairs. This resilience helps maintain the functionality of vehicles and equipment, ensuring they are always ready for deployment. The durability and flexibility of polyurea make it an ideal solution for protecting assets from the rigors of military use.

What are the advantages of using PAXCON PX-2100 as a spall liner in armored vehicles?

PAXCON PX-2100 offers superior protection by capturing and containing fragments from ballistic impacts. When applied over armored panels, it prevents spall, or the ejection of fragments, which can cause secondary injuries. The high-tensile strength and elasticity of PAXCON PX-2100 ensure that it effectively holds these fragments in place, enhancing the overall safety and effectiveness of armored vehicles in combat situations. Additionally, if an armored panel is damaged, it can be easily removed and repaired, ensuring quick and efficient maintenance without compromising vehicle integrity.