At Ultimate Linings, we’ve seen our polyurea coatings put to the test in just about every environment imaginable. Marine conditions, however, demand a particular kind of toughness. Between the constant surge of saltwater, the push and pull of tidal currents, and the relentless presence of marine organisms, wood pilings can break down faster than you might expect. That’s why our partner, Robbins Manufacturing, took a forward-thinking approach. They combined their Wolmanized® CCA Heavy Duty™ pilings with our polyurea coating technology, creating what’s now known as Marine Pile Guard.

I want to walk you through what this solution brings to the table—straight from the perspective of someone who’s spent years helping customers find the right coating for the right job.

What is Marine Pile Guard, Exactly?

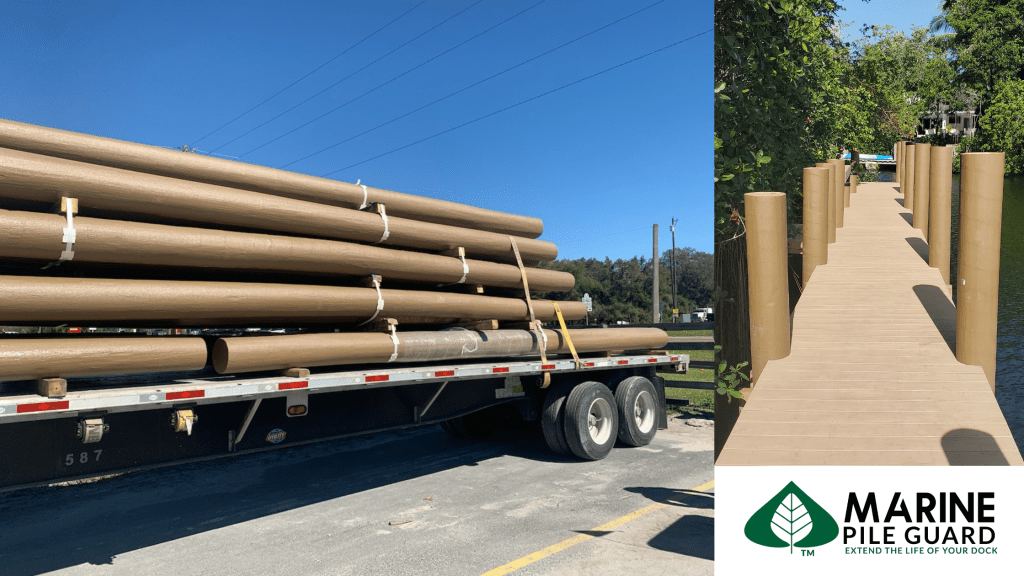

Simply put, Marine Pile Guard is about wrapping a treated wood piling—Robbins Manufacturing’s Wolmanized® CCA Heavy Duty™—in a layer of polyurea. This coating forms a tough, slip-resistant, and watertight seal that looks a bit like vinyl or ABS plastic. But it’s not just about looks; it’s about keeping water, marine organisms, and everyday wear and tear at bay.

Why Polyurea for Marine Pilings?

Polyurea is known for its versatility and durability. In this marine application, it protects the piling from rot, marine borers, and other organisms that love to chew up unprotected wood. By stopping water from creeping into the wood fibers, we’re also reducing the likelihood of those fuzzy, splintered surfaces you sometimes see when wood gets overly saturated. This combination of moisture resistance, abrasion resistance, and a stable surface just makes sense—especially in places where the ocean’s trying to wear everything down.

Breaking Down the Advantages:

- Starting with a Strong Base:

Robbins’ pilings are treated to a retention of 2.50 pcf, which means they’re built for the long haul in harsh marine settings. The wood’s properly dried to ensure the polyurea bonds perfectly. We typically apply about 60 mils—just thick enough to provide a robust protective layer, without getting unwieldy to work with.

- A Barrier that’s Environmentally Conscious:

Encasing the wood in polyurea helps prevent any preservatives in the piling from leaching into the water. That’s good news for everyone—local marine life, the broader ecosystem, and any environmental compliance standards you’re trying to meet.

- Tough Defense Against Marine Organisms and Moisture:

Marine organisms and water infiltration are the big culprits here. The coating forms a shield, stopping wood-boring organisms and slowing internal moisture that leads to structural damage. The result is a piling that stays smooth, stable, and sound.

- Easy on the Jobsite:

Even with the coating in place, these pilings can be drilled, cut, and installed without much fuss. If the coating gets scraped or nicked, repair kits make it a quick fix so you’re not sidelined by time-consuming maintenance or rework.

- Long-Term Durability Means Less Downtime:

By giving the piling an extra layer of armor, you’re reducing how often you need to do repairs or replacements. That translates directly into cost savings and less time spent wrestling with problems down the line.

- Non-Leaching, Eco-Friendly Protection:

Polyurea’s inert nature means it won’t leach harmful chemicals or materials into the surrounding environment. This ensures that even in prolonged exposure to saltwater or other marine conditions, the coating remains stable.

A Product of Collaboration

At Ultimate Linings, we supply the polyurea coatings and share our know-how on application best practices, equipment, and troubleshooting. Robbins Manufacturing brings their decades of experience in producing high-quality wood products. Together, we’re creating a solution that’s greater than the sum of its parts. Marine Pile Guard isn’t just a concept—it’s a tested, reliable system that’s ready for the real-world conditions out on the water.

Why Consider Marine Pile Guard for Your Next Project?

It’s straightforward: You want a piling that lasts longer, stands up to harsh conditions, protects the environment, and doesn’t complicate your installation process. Marine Pile Guard checks all those boxes. We know from experience that polyurea can be a workhorse in challenging environments, and marine settings are no exception. If you’re tired of dealing with split, rotten, or compromised wood pilings, this might be the solution you’ve been looking for.

In Closing

This is just one more example of what polyurea can do when paired with a well-chosen substrate—in this case, Robbins Manufacturing’s Wolmanized® CCA-treated piling. We’ve seen it in action, and it works. Whether you’re building a new dock, renovating a marina, or working on a pier that’s been battered by the elements, Marine Pile Guard is worth considering. Feel free to reach out to Robbins Manufacturing for more details on their products, or get in touch with us at Ultimate Linings if you want to talk coatings. We’re here to help you find the right polyurea solution for your next marine project.

Robbins Manufacturing Contact:

Website: https://robbinsmanufacturing.com/

Phone: (813) 971-3040